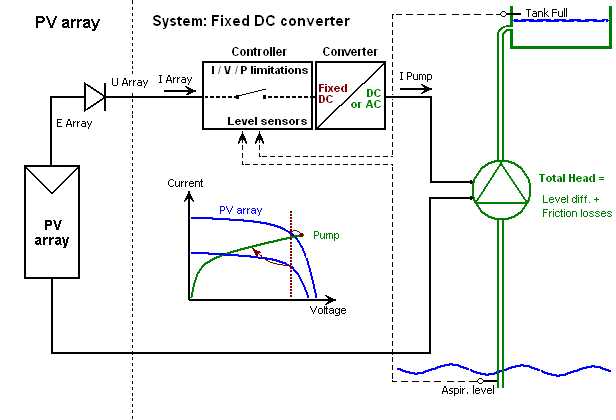

Regulation: Fixed DC input converter

Use of a DC-DC converter (Power Conditioning Unit) shows a much favourable figure than direct coupling. This cheap electronic device absorbs the power of the PV array at a fixed voltage, and behaves as a current generator for feeding the DC-motor of the pump.

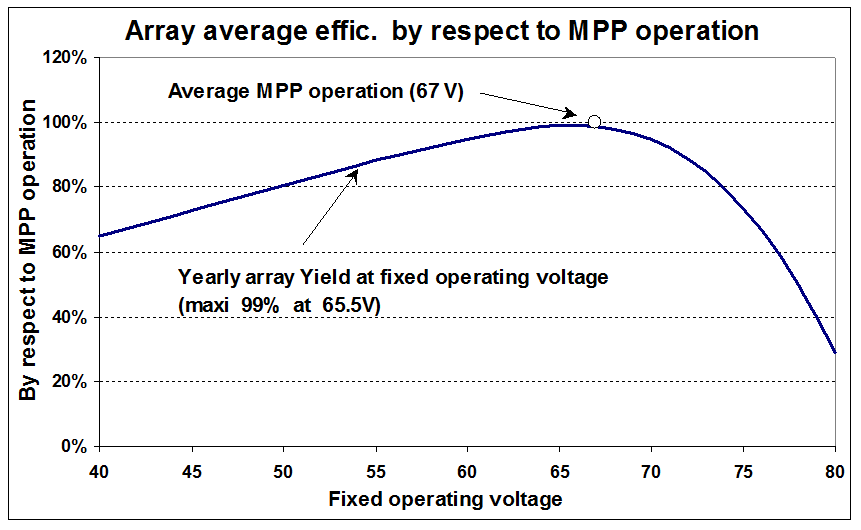

At the input side, the voltage may be chosen close to the maximum power point, and stays quite near for any irradiance. On most commercial DC-DC devices, the input voltage may be adjusted by hardware. PVsyst includes a specific tool optimisation for determining the optimal DC voltage setting.

Performances are only related to the array and weather data, they don't depend on the pump configuration.

At the output side, the power is supposed to be transmitted to the motor at the optimal current/voltage point corresponding to the available power.

For AC pumps, a PCU (DC or MPPT converter) suited for a given pump is usually proposed by the pump's manufacturer. It is supposed to fit the inputs requirements (voltage and frequency) for proper operation.

Efficiency

Nowadays, the converter efficiency is usually of the order of 95% in the high powers region. This efficiency drops toward low powers as other similar devices like inverters. It is treated as such in PVsyst: an efficiency profile is constructed using the maximum and "euro" average efficiency, defined in a similar way as for inverters.

By the way, efficiency drop often arises at powers which are below the hydraulic threshold of the pump; therefore it doesn't affect the normal running.

Of course the DC-DC converter also plays the role of a "Booster". The starting high current is usually required under very low voltage, therefore low power.

You can have a look on the Results, which confirms that the Fixed Voltage DC technology gives performances approaching the MPPT, and is not very sensitive to the fixed voltage.

Step-down technology

We have to point out here a design constraint:: most of the DC-DC converters operate on "step-down" principle. This means that they cannot deliver a voltage greater than the input voltage. Therefore the PV-array MPP voltage should be over the maximum voltage required by the pump at the maximum desired flowrate.

This means for example that when using standard pumps designed for 230VAC grid operation, the PV array should deliver at least 325V for obtaining undistorted sinus at the pump.

This "step-down" limitation can be taken into account by the simulation only when the voltage behavior of the pump is well defined. With pumps specified only by power curves, it is neglected.