Battery aging

The simulation evaluates the wear ans tear of the battery, which depends on the running conditions, and therefore the investment to be planned for its replacement.

The battery wearing state is evaluated according to two phenomena:

- a "static" longevity, of the battery is a "fatal" aging, arising whatever the battery is in use or not.

- a deterioration due to use, depending on the number of cycles and the depth of the discharge at each cycle.

Static aging

A battery is a chemical object, which may be subject to slow degradation along the time. In the database, we usually consider the degradation time as the warranty duration specified by the manufacturer. However this is obviously an extremely uncertain parameter, depending on multiple environmental conditions during the battery use. The battery longevity is usually defined for a reference temperature of 20°C or 25°C.

Lead-acid batteries

In Lead-Acid batteries, the static degradation is mainly related to the sulfatation of the electrodes, and the stratification of the electrolyte (except Gel technologies). It depends on many factors: maintenance, temperature, deep discharges, discharge rate, etc.

An important parameter is the temperature. Most specialists agree for saying that above 25°C, the battery static lifetime will decrease by a factor of 2 every 10°C increase. I.e. when permanently kept at 45°C, the battery life is divided by 4 ! Therefore in hot countries, the battery should be placed in a local as cool as possible. And the question of installing an air conditioning device deserves to be analysed; this could be activated only during day, when the PV production is available.

Li-Ion batteries

Many Li-Ion datasheets mention a warranty of 10 years. We don't have any information about the Li-Ion batteries degradation according to the temperature. These are probably less sensitive to the operating temperatures. The manufacturers often specify a maximum operating temperature of 45°C to 50°C.

Cycling aging

The second component is related to the use intensity of the battery. When using the battery (charging/discharging), there is some wearing, resulting in a slight diminution of the real capacity.

Datasheets usually specify a maximum number of cycles, for a specified depth of discharge (DOD). The end of life corresponds to a diminution of the capacity, usually down to 80% of the nominal capacity (sometimes 70%).

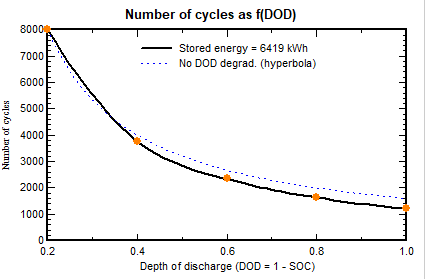

This number of cycles may be interpreted as a global stored energy along the life. For example, 2000 cycles at 40% DOD are equivalent to 1000 cycles at 80% DOD. We can consider this global stored energy as a number of full cycles at 100% DOD. Therefore the number of cycles for any DOD is simply NbCycles (100%) / DOD, i.e. an hyperbolic function of DOD.

In the reality other factors have an influence on the maximum number of cycles:

- High charging/discharging rates increase the wearing. This is naturally taken into account during the simulation, by normalizing the number of cycles contribution calculated at each hour to the real capacity of the battery at the concerned discharging rate (remember that the capacity is dependent on the charge/discharge rate).

- High depth of discharge may also damage the battery, especially with Lead-acid batteries. Therefore an additional number of cycles proportional to the DOD may be substracted from the normal hyperbolic behavior.

Use in the simulation, SOWstatic and SOWcycles

During the simulation, for each time step:

- The static ageing state is decremented as a function of the battery actual temperature as defined by the user for the simulation. This is stored in the simulation variable SOWStatic (SOW stands for "State Of Wear").

- The dynamic ageing state is accurately evaluated as function of the discharging current and the depth of discharge for this hour and the curve above. It is stored in the variable SOWCycle.

The final SOW state is the minimum of both states.

Both initial wearing states may be specified at the beginning of the simulation, allowing to chain the real state over several simulation years.

The SOW evolution value along the years determines the Battery lifetime, which may be used in the economic evaluation for the replacement costs.

If, during the simulation, one of these SOW states attains zero, the battery is supposed to be replaced and both SOW are reset to 100%. This is namely apparent in the Aging tool.

Capacity function of the battery age

The effective capacity is indeed decreasing according to the SOWCycl value; we admit that this diminution is linear.

Now the maximum number of cycles is specified by the manufacturer in such a way that the capacity is decreasing downto 80% at the end of life. NB: Recently some few datasheets mention an end of life at 70%, which significantly increase their foreseen number of cycles !

This capacity reduction is not yet taken into account in the capacity evaluation during the simulation, so that PVsyst doesn't take this effect into account when studying the ageing of stand-alone systems. A model should be developed in the future.